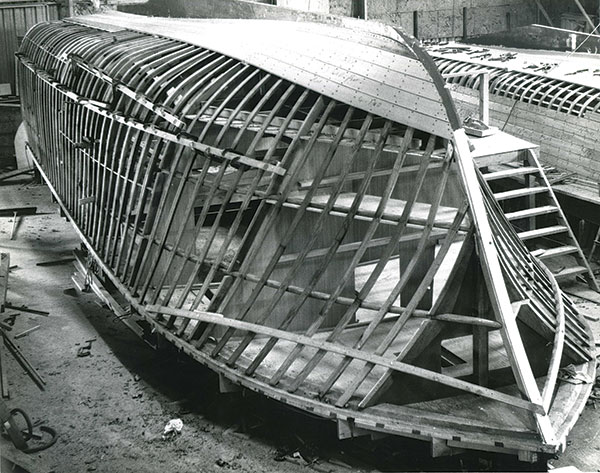

Back in 1964, when two brothers from New Jersey purchased a little-known yet admired boat company named Peterson-Viking Builders that built wooden sport-fishing and cruising boats, no one could have predicted what their new company would become in the next 50 years. The Viking Yacht Co. was formed when Bill and Bob Healey created their family-based joint venture, and the rest, as they say, is history.

Today, Viking enjoys the hard-earned position as the undisputed leader in the production sport-fisherman market, but it wasn’t always so. It took lots of hard work, dedication and vision to take that fledgling boat company and transform it into the powerhouse it is today.

Much of the company’s story centers around the people involved in the Viking family. The company has remained under the private ownership of the Healey family for the past 50 years, and the Healeys intend for it to remain that way. That’s a remarkable feat in today’s business world. Much of the rest of the boatbuilding industry has been subjected to repeated turnovers and turmoil in terms of both ownership and management personnel. Corporate ownership is the norm in much of the boat business but not at Viking.

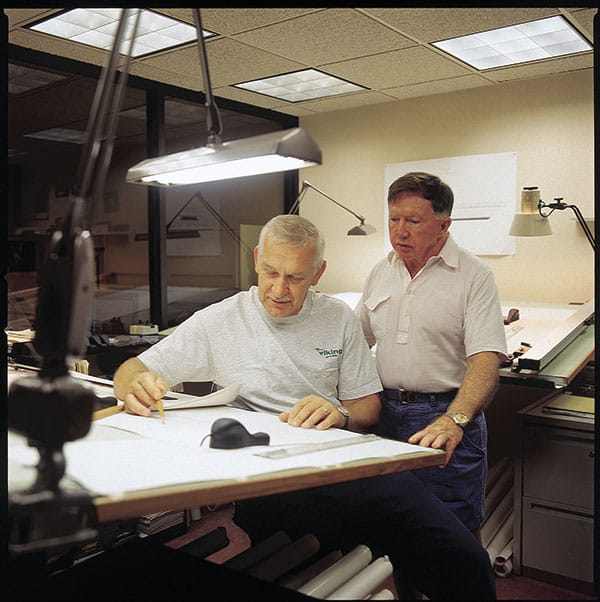

The brothers each possessed a skill set which suited the new endeavor perfectly. Bill Healey was, and is, a passionate boatbuilder; it’s what drives him and makes him the best at what he does. Bob Healey, on the other hand, is the businessman with a head for money, so when you put the two together, you have the perfect team for the boatbuilding business.

Keeping It Private

Pat Healey, Bill’s son, serves as president of Viking Yachts. “We’ve always had private ownership,” Pat says. “And that has allowed us to make decisions and act on them instantly. There’s no corporate board to consult … just us.” This flexibility has served them well, and Pat points out that Viking’s excellent dealer network is also privately held with a keen sense of entrepreneurship.

In addition to the Healey family itself, many of Viking’s employees have been with the company for decades, providing a consistency many other builders lack. “It’s all about the people, from the workers on the floor to the management team,” Pat says. “We’ve all been able to integrate together to form a complete, 100 percent team with only one goal: to build the very best boat possible.”

Trendsetter

In the early days, Viking built boats much like some Carolina boatbuilders — assembling the boats on frames at interval-based work stations. But that changed in 1971, when Viking built its first all-fiberglass model, the Viking 33 Convertible. The 33 became an overnight hit and launched larger models that brought the company more fame in the fish-boat community.

The next milestone boat debuted in the fall of 1972, when Viking rolled out what would become one of its bestsellers ever: the 40 Convertible. Viking sold more than 600 40- and 41-foot models over the next 16 years, and every Viking built since has shared this basic hull design, with evolutionary refinements being made to accommodate steadily increasing available horsepower and speed.

Viking continued to grow during the ’80s, and the company expanded into a new market when it acquired Gulfstar Yachts, a West Florida-based motor-yacht builder whose designs were considered among the best in the industry. But fishing boats always made up the backbone of the company, and by 1990, Viking offered a complete line of convertibles as well as motor yachts.

Dark Clouds

In 1991, however, the boatbuilding industry suffered one of its most serious setbacks with the implementation of the infamous “luxury tax” on Jan. 1 of that year. A 10 percent tax was automatically tacked onto boats with price tags greater than $100,000. At that time, the National Marine Manufacturers Association estimated that 10,000 to 15,000 boats would be subject to the tax, and many of those were Vikings.

The luxury tax caused Viking to fall from 1,500 employees and two plants to just 80 employees working in a single plant. The entire marine industry suffered massive plant shutdowns, with many related closures in businesses including engine manufacturers, equipment producers and many more. The Healey brothers were forced to cash in some of their personal savings to keep the company afloat.

Bob organized a national grass-roots campaign to fight the tax. He took bus loads of out-of-work boatbuilders to Capitol Hill to show Congress precisely what this new tax had done. His leadership was instrumental in overturning the ill-advised measure, which was officially repealed in August 1993. It is interesting to note that Viking’s decision to remain open despite dismal sales attributable to the luxury tax allowed the company to tool up new models. So when the tax was lifted, Viking was uniquely poised to acquire new market share.

More milestones occurred in the ’90s, as Bill and Bob founded the Recreational Fishing Alliance in 1996, a nonprofit organization formed to promote sustainable fisheries and a healthy marine environment. Viking has contributed several million dollars to the RFA to date.

Game Changer

One of the most significant events in Viking history occurred in 1997, when the company introduced the 55 Convertible at the Fort Lauderdale International Boat Show. This game-changing model looked vastly different than previous Vikings and proved to be an instant sensation. Pat spent a lot of time asking fishermen what they wanted to see in a boat, and he incorporated many of their ideas in the new 55.

“The 55 was the first boat that took this company in the custom-boat direction,” Pat says. “We spent a great deal of time asking captains, mates and owners what they wanted and forged strong relations with custom builders like Roy Merritt to trade ideas. The result was the 55.” Pat became personally involved in major blue-water tournament fishing and got to know many of the players in that specialized game, giving him invaluable insight into the potential market from the feedback he received from other tournament participants.

Viking sold more than 150 55s in just six years — a remarkable achievement for a boat this size — and the 55 led to larger models that shared the same attributes. “The 55 started us down the path to create the 61 (1999), 65 (1998) and 74 (2004) Convertibles,” Pat says. “And each of those has been a tremendous success.” These boats marked a radical design shift away from older trunk cabin designs to flush-deck boats with rounded lines and big, teardrop windows.

Always known for building good-looking boats that performed well, the company upped the ante in 2000, investing more than $10 million to upgrade and improve its manufacturing facility, which now encompasses 810,000 square feet. Parts are cut using a five-axis profiler milling machine acquired in 2004, the largest of its type in the marine industry. New hulls are tank tested as scale models for hydrodynamic efficiency, further enhancing Viking’s unsurpassed reputation for seaworthiness, speed and a dry ride.

Viking opened a new service facility in Riviera Beach, Florida, in 2002 for the convenience of Viking owners who spend winters down south. The facility features slips for in-water work, as well as land storage to handle larger projects and outfitting. Viking soon after created Atlantic Marine Electronics and Palm Beach Towers in Florida to facilitate the rigging process.

Continuous Innovation

Throughout the 2000s, Viking continued to innovate and introduce new models, including the 68 Convertible, the Enclosed Bridge 74 Convertible, the 52 Open, the 64 Convertible, the 68 Enclosed Bridge Convertible, the 64 Enclosed Bridge Convertible, the 54 Convertible and the 60 Enclosed Bridge Convertible, along with a brand-new series of West Coast sport-fishing models. Designed with innovative flying bridge arrangements, tuna towers, outriggers, and fore and aft bait stations, the models raised the bar by producing a turnkey tournament machine built strictly to West Coast standards for Southern California and Mexican waters.

Next came the 50 Convertible and other milestones in manufacturing, including advancements in resin infusion in the creation of tankage, propeller boxes, engine-room vents and other components. In March 2008, the hull mold of the 82 Convertible was lifted from its plug in preparation for the building of Viking’s new flagship. As the decade ended, the 82 Convertible, the 57 Convertible and the 46 Convertible were

introduced, along with a new 46 Open, the 76 Convertible and the 82 Enclosed Bridge Convertible.

Viking debuted the 42 Convertible with its innovative pod drive system in 2010. The company also presented the new MTU V16 Series 2000 M94 engines rated at 2,600 hp in a Viking 82 Convertible at the Miami International Boat Show, blowing away the public’s expectations on performance in a boat of that size. At the Fort Lauderdale International Boat Show in October of that year, the new Viking 70 Convertible premiered along with the new 42 Convertible.

Going Green

2011 saw the introduction of the 70 Enclosed Bridge Convertible, the 66 Convertible and the new 42 Open. Viking also enhanced its reputation as a green company when it upgraded its production facility by adding solar power cells covering about 17,000 square feet of roof space and weighing some 50,000 pounds. Exactly 798 solar panels, each generating 250 kWh per year, were installed on the building’s roof, providing enough power to supply the needs of two major plant buildings for a year. This installation enabled Viking to reduce its carbon dioxide emissions by 3,000 tons.

Viking began building a tri-generation plant in 2012 to produce its own electricity utilizing six turbines. By reducing electrical costs, the company estimated the project would be paid for in three to four years. In the midst of all that, the company also managed to introduce a 66 Enclosed Bridge Convertible and an all-new 55 Convertible. And Viking announced a 92 Convertible at its 2012 June dealer meeting. At the 2012 Fort Lauderdale International Boat Show, the Viking 55 earned rave reviews from a number of marine journalists for its style and performance and, in doing so, provided a hint about what was to follow. In December of that year, Viking’s tri-generation plant came online.

The new Viking 62 Convertible premiered at the Viking Yacht VIP Boat Show Preview in February 2013 at Viking’s service center in Riviera Beach, and the 62 Enclosed Bridge made its first appearance at the Yacht & Brokerage Show in Miami. As we move through 2014, all eyes are focused on the impending completion of the 92 Convertible and a new 75 Motor Yacht, both of which were in assembly as this story was being written. Viking recently opened a fourth assembly line to accommodate current production models as well as future builds, which include two all new 52-footers.

Clearly, Viking is a company on the move and seeking to further consolidate its position as king of the production-boat mountain. “We’re working in a much smaller market then we were in the heyday of boatbuilding,” Pat says. “In the good old days, the large sport-fisherman market sold 300 to 350 boats a year. Now, it’s a 100-boat-a-year market, but thankfully, we get about 60 of those.”

Pat is bullish on the future. “I was born and bred as a boatbuilder, and we’re a dying breed,” he says. “But we’re set up to perpetuate this legacy and keep this company going for another 50 years. We intend to out-design, out-engineer and out-perform our competition, just like we’ve always done.”

Bob has a great saying that Pat likes to repeat. “My uncle likes to say, ‘We’re at the top of the mountain; we love the view, and we’re not giving it up,’ ” Pat says. That pretty much sums up the Viking Yacht Co. and the extraordinary people who’ve made it what it is today: the cream of the crop in the production boatbuilding business.