There have been some quiet conversations circulating for a while now about a special new hook design, something so unique that it could be a real game-changer. Something big. The project was about as closely guarded as one can be in today’s modern age of connectivity and social media. Until now.

Watch: Learn more about how Sta-Stuk hooks work.

Release Marine founder and president Sam Peters has fished for marlin all over the world with some of the best captains and crews, and he’s also witnessed his share of gut-wrenching frustration along the way. The No. 1 cause of his heartburn? Pulled hooks and lost fish.

A skirted trolling lure is one of the best ways on the planet to pick a fight with a blue marlin. The drawback is a hookup-to-release ratio that hovers somewhere around the 50 percent mark. Sure, there will be days where you might go 3-for-4 or 6-for-8, but then the next day it’s 0-for-3, 1-for-4. If you’ve managed anything over 50 percent for a full season’s average, well, that’s a win for most fishermen.

How is it possible that this big fish that’s hooked and jumping all over the ocean for an hour or more manages to come unhooked so often? Peters wondered. There must be a reason.

Hook Science

The first person Peters turned to was an engineer who had previously worked with him on projects for Release Marine. “I learned a lot,” he says. “A J hook is just a lever, and you need to have a long shank on it in order to drive the hook point home, which in this case is somewhere around the mouth of a blue marlin. But the shank is also your worst enemy when it comes to fighting that fish. When you pull on the shank from any direction other than directly forward in line with the point, you’re creating rotational torque. That’s the force that’s working against you, causing the hook to twist out of the fish.”

Think about changing a flat tire on your truck. If you use a lug wrench with a 12-inch handle, you’re applying rotational torque. If you use one with a 6-inch handle, you’ve effectively halved the amount of torque, and you’ll have a lot harder time loosening those lug nuts. The same principle applies to the shank of a hook once it’s embedded in a marlin.

So how do you overcome rotational torque while still achieving the necessary leverage to drive home the hook point on the strike? What if you could somehow reduce the length of the hook shank, and then find a way to hold it together so that it would break apart on the bite? As it turns out, it’s much easier said than done.

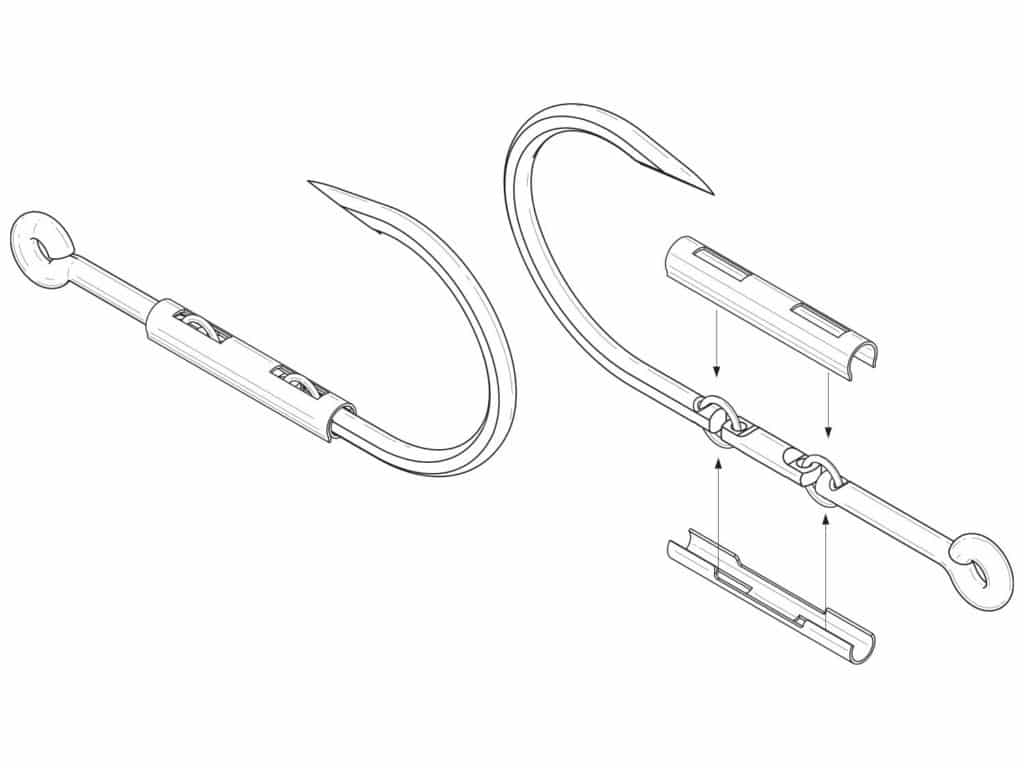

“I started in 2017 with some really crude prototypes,” Peters says. “I was hand-drilling them in my shop and using 80-pound-test split rings with a swivel in the middle. I tried 10 different ways to hold the thing together, and none were successful until I came up with the concept of using an inner and an outer stainless-steel clip system.” All this with soaring costs, and while submitting a patent application, hoping it would be approved. While helping him film a short video of some initial testing in his company’s manufacturing facility, Release Marine vice president Glenn Griggs remarked, “Wow, that hook really stays stuck, doesn’t it?” The name perfectly summed up the purpose, and the Sta-Stuk brand was born and subsequently trademarked.

If At First You Don’t Succeed…

Peters knew that field-testing the new hook design would be critical to success. No amount of time spent in the shop can reproduce real-world conditions on the water, or the violence of a blue marlin’s crash bite. He consulted with a number of reputable fishermen, including captains Bubba Carter, Charles Perry, Ray Rosher and others too many to name, then he set out to test his new hooks. First stop: the seamounts of Costa Rica, fishing with Carter and Perry on Tijereta in June 2017.

“Even though it’s mostly a bait fishery, I knew those fish would eat lures, so I had Andy Moyes send us some stuff just for that trip. I had 10 different prototype hook designs to test,” Peters says. “We hooked the first six fish…and jumped off every single one of them. It was an abject failure. We caught one out of 11 on that trip; I was frustrated beyond belief and very disappointed, as were Bubba and Charles.”

But as with any new project, trial-and-error testing is a critical component to ultimate success. Peters had unknowingly made two key errors in the design, so he went back to the drawing board. Each round of engineering and manufacturing of the clips and hooks was an investment of more than $2,000, not to mention the expense of travel and charter fishing. Stronger clips and another seamount trip with Carter the following year produced a slight bump in the catch ratio, but it still wasn’t up to Peters’ expectations for the project.

“After another 45 days of continual prototyping and testing, I finally figured out how long the hook shank had to be in order for it to penetrate effectively, and the correct breaking strength for the clip system on the bite—that was the ‘aha!’ moment,” Peters says. “We also started using three welded rings instead of a swivel in the middle, which accomplishes the same goal of allowing the hook to rotate freely once the clips come apart.”

They headed to Cape Verde in spring 2019, where the team would be dealing with much larger blue marlin on heavy tackle—a distinctly different fishery than in the Pacific. “If you’ve been blue marlin fishing long enough, you understand that 200-pounders are just like immature teenagers—both are erratic and really all over the place on the bite. The bigger fish are much more methodical in the way they approach a lure and then eat it. I had done a lot of research, and I knew that Cape Verde would be the place to test these new prototypes.”

Bates and Company

He needed a captain with considerable experience in lure-fishing, one who had kept good bite data over a long period while also fishing in the same waters with little outside influence—a near-perfect beta site for prototype testing. This led to an introduction to Capt. Marty Bates of La Onda Mila. Bates had first come to Cape Verde in 2006 and has since settled there. Peters was also logging every single bite—even those halfhearted knockdowns and bill slaps that we all experience from time to time, as well as the placement of the hook in the fish, amount of drag, and fight time, as well as lure make, color, and position in the spread. He documented everything. “I wanted this to be as scientific as possible,” he says. “We needed a lot of blue marlin bites over multiple years, season after season, and Cape Verde was the place to do it.

“When I showed [Bates] the hooks on that first day, I could tell he wasn’t sold on it,” Peters continues. “For one, he didn’t think they were strong enough. But it was my charter, and he let us fish the way we wanted to.” In the first four days, they went 10-for-10 on blue marlin. “After we caught the first six in a row, Marty looked down from the bridge and said he was now a believer, and then we caught four more,” Peters says. “We were consistently catching just about every fish we hooked.” He notes that at one point they were 19-for-21, and that’s straight up logging every single bite, not fudging any of their numbers. “Marty and I were both just stunned in disbelief,” he says. “This was our 10th prototype. I still had some fine-tuning to do, but now we were getting a cleaner, more consistent breaking tension with the clips.”

Over the course of the prototype modeling, Peters used three different hook styles from three different manufacturers, which brought up another interesting point. “All of the stuff we’ve done for the past 40 years—going from two hooks to one hook, free-swinging to stiff rigs, knife points, conical points, a curved shank or not—all of those changes have basically resulted in no increase in the overall hookup percentage,” he says. “I bought five of the most popular brands of hooks, stacked them on top of one another, and there isn’t a 1/16- to ⅛-inch difference in any of them. All of our frustrations over the past four decades, and we haven’t moved the needle in our favor at all.” After working with several manufacturers, Peters finally settled on Fudo hooks. “Jason Levine at Fudo really understood this project and the potential we have, and it’s been a great relationship,” Peters says.

Protecting the Brand

From his experience with Release Marine and holding nine US patents, Peters knew that he had to fight hard to protect not just the Sta-Stuk product, but the entire process as well. “I knew right away that since I’m not a hook manufacturer, I’d get knocked right out [of the business] unless it was fully patented,” Peters says. What he needed was a utility patent, which protects the entire concept and not just the shape of the hook. “When you think about it, hooks haven’t changed all that much in the past 3,000 years,” he says. “In fact, Forbes has called the fishing hook one of the top 20 most important inventions in the history of the world—it’s fed the people on this planet a thousand times over. A design patent is just a simple drawing of an item that says, ‘This is my design.’ A utility patent is much more comprehensive and is a lot more expensive to file because it covers the concept of what the product does and why it works. This is the first multipiece hook that’s held together by a clip system that is designed to break apart at a specific amount of pressure in order to reduce the rotational torque while you’re fighting a fish.” In summer 2019, the patent was approved, and the Sta-Stuk brand was now fully protected. The next goal: 100 blue marlin bites.

Return to Cape Verde

In spring 2021, I was invited to participate in additional field-testing with Peters and Bates in Cape Verde. Our first day, we trolled from the capital port city of Mindelo west to the island of Santo Antão, where we would spend the first few days of the trip fishing the Northwest Bank, which rises to within 700 feet of the surface from the surrounding abyssal depths.

Peters was specific in the way he fished the hooks. “We’ve learned that you want to fish with the rigger clips set at 10 pounds and the reel drag at 14 pounds on the bite,” he says. “At 10 pounds on the clips, that’s enough to stick the point of the hook in the fish, and 14 pounds is enough to engage the rotational torque and pop the sleeves in the hook. On every marlin that we’ve caught, the sleeves are popping, so that proves that we are reducing the amount of rotational torque on the shank.” The hooks are rigged using 400-pound-test, 19-strand flexible cable with the eye of the hook in the end of the lure skirt, per IGFA rules. We chose to fish a spread of four lures on 80-pound-test tackle. Bates does pull two mudflap dredges, but we chose not to use bridge teasers or to pitch-bait in order to get as many lure bites as possible.

In the four days I fished with the team, we ended up going 6-for-9 on blue marlin and 1-for-1 on whites—a 70 percent hookup-to-release ratio. One of our bigger blues was lost after 20 minutes; it was bill-wrapped and came up windshield-wiping before we could pull the slack out of the line, and one more was a real junk bite, more of a bill slap from behind than an actual attempt to eat the lure—but hey, those count too. “You have certain fish that you’re just never going to catch on any hook,” Peters says, as he diligently logged every bite. The rest of the team fished for a few more days after I headed home, eventually running the tally to 11-for-14 on blue marlin, for a bite-to-release percentage of 78.57. We were nearly 100 percent on the flat lines, which accounted for the majority of our marlin bites. The largest blue was an estimated 800-plus-pounder, with another 700-pounder and several 500-pounders. The wahoo were ever-present throughout the trip, with the Sta-Stuks proving exceptionally adept at hooking them. Even though we were using standard marlin lures and not specifically targeting wahoo, we still went 6-for-9 on 30-pounders.

Read Next: Create jaw-dropping sashimi with these tips.

Another factor to consider is the weather. Rough seas adversely affect any lure’s hookup ratio when the riggers are swinging up and down as much as 15 to 20 feet in a beam sea, and it was rough during our time in Cape Verde. I have to believe that in a calm-water fishery like Kona or Madeira—where a marlin can really zero in on the lure—the hookup ratios would skyrocket.

What about durability? To date there have been no ring failures on any size blue marlin; the hook will straighten before the rings fail. Peters has logged more than 35 hours using a forklift and a certified scale in order to find the true failure points. At 400 pounds, the welded rings began to stretch just before the cable broke. “There’s no way you could break these on a fish,” he says.

The Parting Shot

After we departed, Bates kept fishing with the Sta-Stuk hooks, as he’s done since 2019. On his next charter trip, No Quarter’s Mike Peet and John Floyd from F&S Boatworks went 9-for-11 on blue marlin, where they also caught a really nice one.

So is the Sta-Stuk hook truly the better mousetrap? The bite data is overwhelmingly positive. On July 20, 2021, at 3:31 p.m. the Sta-Stuk project crossed the 100-bite threshold—with 75 of those blue marlin wired to the boat—for a 75 percent ratio, and that’s counting all those halfhearted bites that didn’t even pop the clips on the hooks. As an outside observer, I was amazed at the amount of sheer effort that has gone into this project over the past four years: the constant research, prototyping and improvements; the scientific approach to logging the bites; the laborious and expensive patenting process; and the attitude that good enough really isn’t good enough. Any way you look at it, this is a truly innovative design that has the real potential to change lure-fishing for marlin as we know it—forever.

For More Information

Sta-Stuk hooks are available through the following retailers. To learn more about Sta-Stuk, visit sta-stuk.com.

This article originally appeared in the December 2021 print issue of Marlin.