No problems, only solutions. That’s always been one of my favorite sayings when coping with boat issues. When something on your rig goes south, there are a few go-to tools I always have on board that can help diagnose where the problem lies and ultimately find a solution, either on your own or with an electrician’s or mechanic’s help.

Fluke T5-600 Electrical and Continuity Tester

A boat’s electrical system is always tricky. How do you find what you can’t see? Most of us have some sort of electrical tester on board, but many of them are confusing and have way more switches and buttons than we will ever require to diagnose our boat’s common issues, and most are too complicated for what we generally need.

So why the Fluke T5-600? It’s easy to use. This tester was suggested to me years ago, and I still use it, so if you want simplicity and a no-brainer tool to test voltage, amperage and continuity, this one is the way to go: one knob, three choices. What could be easier?

The first setting is voltage. When switched to voltage, it will automatically determine both how much voltage you’re dealing with and also the type of voltage: AC or DC. This setting is great to see if you have any power at all, or if that particular voltage is too low or too high. Whether it’s batteries, outlets or electronics, you will be able to test and easily check the power you have coming into the component.

Recently I helped troubleshoot a battery issue with Jimmy DiPastino of Florida’s Ward’s Marine Electric. DiPastino is one of the best in the business, and I have always learned a lot from him. After installing Shark Byte’s brand-new batteries, a few months later, they were dead. To get the boat running again, we paralleled the engine and house batteries. First, DiPastino checked the voltage coming from each battery. One battery was steady at 13 volts, while the other was at only 7 volts. Obviously, a bad battery, right? But why?

Testing the battery-charger output was next. It was up around 31-plus volts, which is way too high and possibly overcharging the battery, so the high voltage took it out. Chargers should be putting out approximately 27.6 volts for a 24-volt system. With the T5-600, we were able to discover that it was not the batteries at all that caused the problem, but actually a bad battery charger, which was putting out more voltage than it should have been.

Watch: The Viking 37 Billfish is certainly a stunner.

Continuity can also easily be checked with the tester. Continuity is the presence of an interrupted, complete flow of electrical current. A closed switch that is operational, for example, has continuity, and there is a continuous flow of power to a device that might be otherwise “off.” Other examples would be to test whether a fuse is good or blown; if a conductor is open or shorted; if switches are operating properly; or if circuit paths are clear.

While doing a continuity test, the multimeter sends a small current through the circuit to measure the resistance. The meter beeps when it detects the closed circuit—the electricity is flowing unhindered in a circular path. Simply put, if you don’t get a beep, the power is not getting through and you have a problem, maybe even perhaps a broken wire somewhere in the system.

The device can also test/measure amperage. It’s easy to use: Simply put the wire you want to check between the forks while the equipment is running.

NonContact, Infrared Laser Thermometer

Mechanic Jack Montgomery taught me a great lesson years ago while I was running the 58-foot Merritt Grander. The starboard engine was running hot. No alarms had come on, but readings were warmer than normal.

To try to diagnose exactly where the problem was occurring, Montgomery suggested taking the infrared thermometer and shooting it at different spots on the engine: water pumps, heat exchangers, transmission coolers, etc. The digital readout will immediately tell what the temperature is at that particular location. As you move the thermometer around the engine, you easily see the hotspots. Comparing one engine to the other verifies your find.

A good example would be if a transmission cooler becomes clogged with debris. The water coming into the cooler might be the same as the other engine, but the water flowing out of the cooler might be much hotter than the other in comparison. This would suggest a clogged cooler. If it traces back toward the engine’s raw-water pump, it could be that the impeller is going bad.

Another time, we enlisted the help of Johnson & Towers mechanic Mike McMann after we found the boat had a bad injector. We knew we had an issue but didn’t know exactly which one of the injectors was affected.

Read Next: Show your outriggers some love with these tips and techniques.

McMann shot the infrared thermometer on each of the exhaust-port entrances to the exhaust manifold, and sure enough, the injector that wasn’t firing was the one that was about 30 degrees cooler than the others. The computer hooked up to the engine didn’t figure it out, but by using some basic mechanical skills, McMann sure as heck did.

I keep a spreadsheet of some critical points on the engines and their temperatures while running at normal operation. If a problem comes up, having a baseline of what temperatures different components—such as coolers, exhaust manifolds and heat exchangers—operate best at can be a huge help.

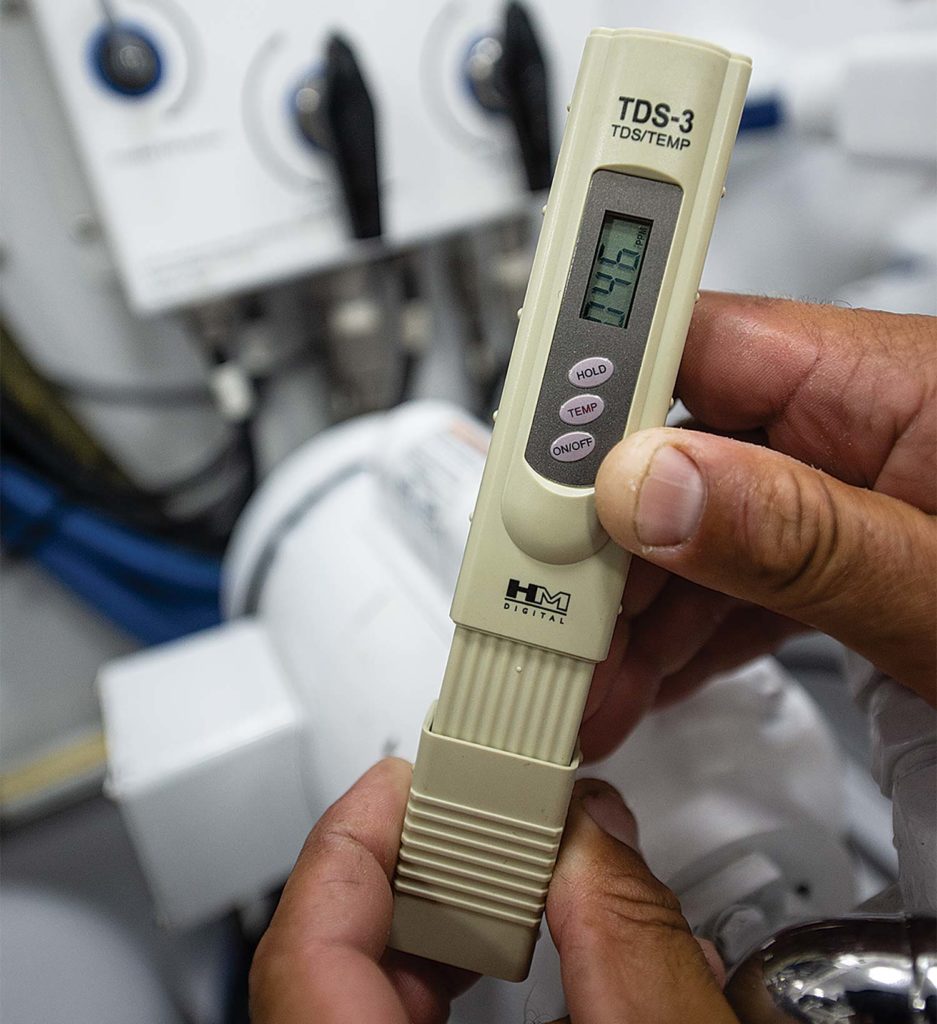

TDS Water-Flow Meter

If you have a watermaker, you need to know what your output water product is. A total-dissolved-solids meter measures the dissolved stuff in your water that makes the water hard. Whether you’re using a built-in watermaker or a portable unit on the dock, having a flow meter makes a world of difference, especially when cleaning your boat.

If you are using a reverse-osmosis system, this is a great tool to be sure the unit is working correctly. Most watermakers will begin making acceptable water at 550 parts per million. If running with flawless membranes, the unit should be able to get that down to approximately 70 to 140 ppm, and a unit processing fresh water at 6 ppm is making near-perfect, spotless water. As membranes get old or deteriorate, you will see your water quality go down, leaving more spots. Once the product water gets up into the 500s, your watermaker will probably fail and cease to make fresh water.

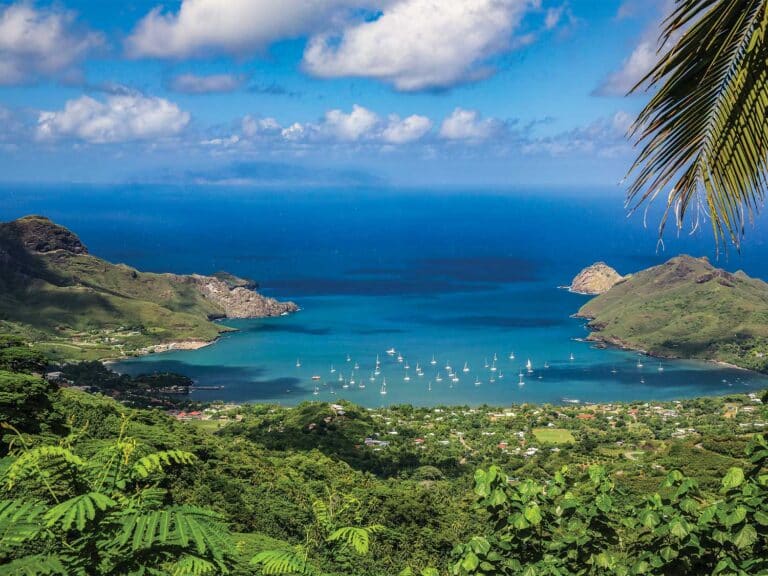

Testing the dock water before cleaning the boat will help you decide if using the dock water in lieu of the water in the tank is worth it. This is especially important when traveling abroad, where dock-water quality can be suspect, at best.

These three tools are essential and can help get you out of a jam while troubleshooting boat issues. They have helped me and many other crews figure out a problem and come up with a solution. I’ll bet they can help you too.