Classic lines, traditional materials and tried-and-true construction techniques are the first things that come to mind when thinking about custom Carolina sport-fishing boats. Jarrett Bay Boatworks has a project underway that will change perceptions of Carolina boatbuilding.

Gary Davis, Jarrett Bay’s director of new construction and design, showed me the project on a recent stop at the facility in Beaufort, North Carolina. The 90-foot hull No. 62 will be one of the most beautiful boats ever built and takes Jarrett Bay’s classic lines to a new level. But appearance aside, this boat will be the result of very specific design and performance parameters requested by her owner. “It’s great to have a customer so focused on the engineering of a boat and the use of advanced materials, some of which have never been used in our segment of boatbuilding before,” says Jarrett Bay president Randy Ramsey.

The company assembled a group of specialists to collaborate on the build, and more are expected to come into the picture during later stages of construction. Davis will lead the project on-site, along with Chad Voorhees, Jarrett Bay’s in‑house product design engineer and naval architect. Together with Ramsey, the duo sought out the best engineers for their expertise in the fields of advanced materials, laminates, weight control and propulsion. “The dollars expended in engineering costs before the first hull member was cut is staggering,” Davis mentions.

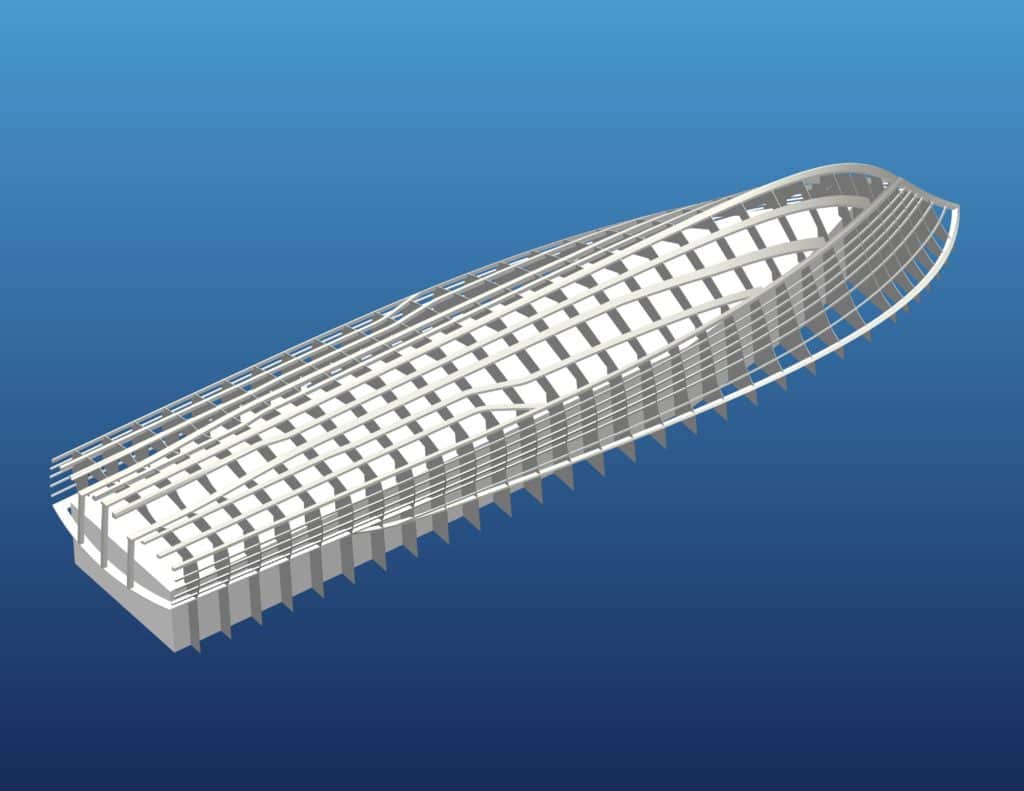

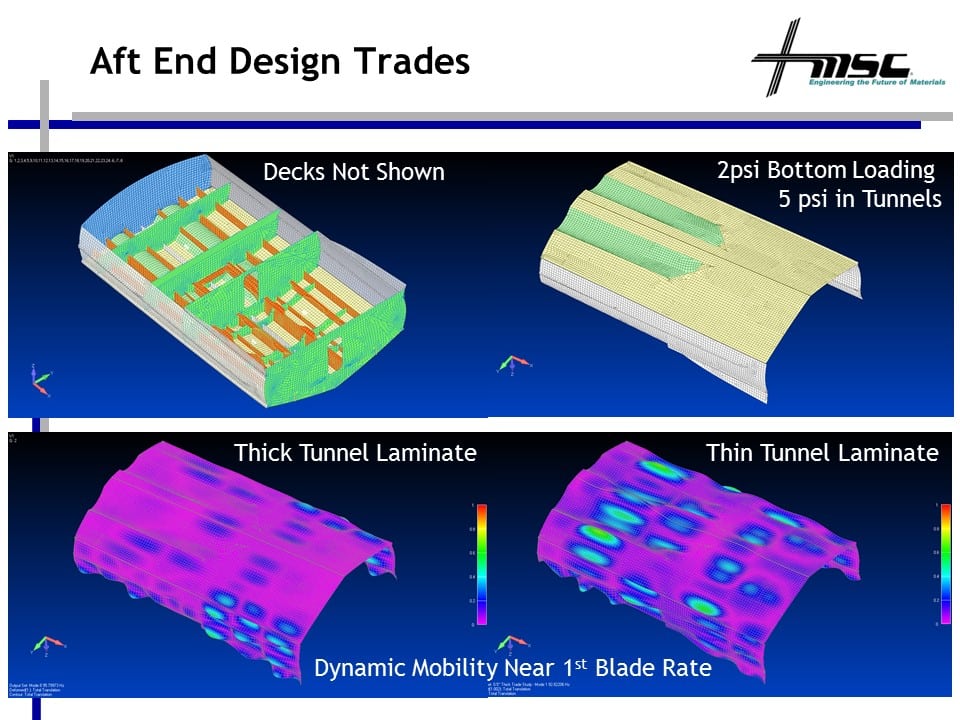

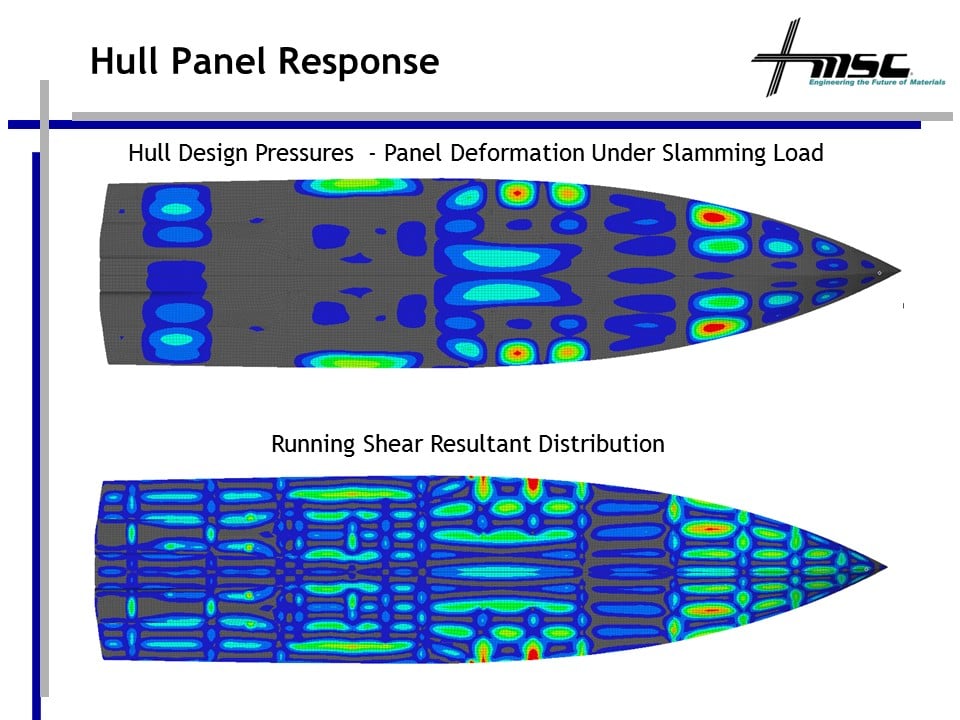

The project incorporates materials and building techniques developed for class boats, like those used in America’s Cup racing, and specialized general aviation aircraft. The actual hull features an atypical stringer system that takes into account the stress loads prescribed by advanced computer software. The stringers and bulkheads are constructed of carbon-fiber cloth encapsulating lightweight coring materials that are vacuum-bag resin-infused to create structures stronger than conventional methods at a fraction of the weight. Similar parameters were called into play in the design of the prop tunnels.

“Each area of the boat is being built to meet very specific weight budgets,” Davis says. That includes attention to the smallest details; the interior design takes advantage of specialized materials to keep the weight down to meet or exceed performance criteria and the predetermined center of gravity for the vessel. “With the hull laid, the stringers, bulkheads and 4,500 gallons of total fuel tanks, we actually came in slightly below the goal weight.”

One of the client’s parameters was to achieve speed and cruising economies unheard of in a vessel of this size so it could travel to far-flung destinations on its own bottom. This needed to be done using the largest engines available, MTU 2,600 hp 16V 2000 M96 diesels, although the client would prefer more horsepower.

“Our prime directive was not to be satisfied with what has been accepted,” Ramsey adds. “In areas where we could find new materials and construction techniques that made sense, we moved beyond the expected into new territory.”

“There is much more to this build than we can make public at this time,” Davis explains. “Some techniques are so revolutionary that we have applied for patents and are awaiting approval.”

The next stop is tank-testing a 20-foot model to check hull dynamics and fine-tune weight distribution for optimum running attitude. The Jarrett Bay 90 is scheduled to splash in spring 2017.