Special delivery: Sign up for the free Marlin email newsletter. Subscribe to Marlin magazine and get a year of highly collectible, keepsake editions – plus access to the digital edition and archives.

“The American dream” describes a belief made popular during the Great Depression that anyone can attain success when presented with the opportunity. Russ Garufi is the embodiment of the American dream. An avid boater and angler since his teenage years on the Chesapeake, Russ spent decades honing his talents in the commercial housing industry before applying that skillset to boatbuilding. Starting from a chicken coop in 1999, Russ has built Titan Yachts into one of the premier builders in today’s sport-fishing market.

Q: Tell me about your childhood. Where did you grow up, and what was your introduction to fishing and boating?

A: I grew up in Prince George’s County, Maryland, and got my first boat when I was 14. It was a 14-footer that I bought from Montgomery Ward. Then, when I was 16, my dad and my brother bought a 21-foot boat with an inboard/outboard V-8. My brother didn’t want to make the payments, so I bought him out. I used to chase stripers and bluefish in it. But when I was growing up, I always remember working. My mother was a resident manager for an apartment complex, and she got me a job with the maintenance guys. I would carry tools and help them with repairs. Looking back, that was really where I learned some of the basic mechanical and craftsman skills that helped me throughout my life.

Q: Before boatbuilding, what did you do for a living?

A: Well, from my early days of doing odd jobs like window replacements and basic carpentry, I just kept going in that field. I’ve always had the ability to look at something and then build it. It’s just a gift. So, at 18 I already had my own company and was subcontracted by Ryan Homes, a national builder. By the time I was 20 years old, my business employed 300 people. I continued that work for years. Meanwhile, I still fished, but mainly only on weekend trips. In 1983 I purchased a 25-foot Grady White and made my first trip to the Rock Pile off Cape Hatteras. I remember we caught two tuna and a wahoo. That was my first bluewater experience, and I loved it. Eventually, I got to a point with work where I moved from subcontracting on housing developments to purchasing, developing and selling the properties. As work grew, I upgraded to a 42-foot Bertam in 1986 that I fished up and down the East Coast for 17 years.

Q: How did you first get involved with boatbuilding?

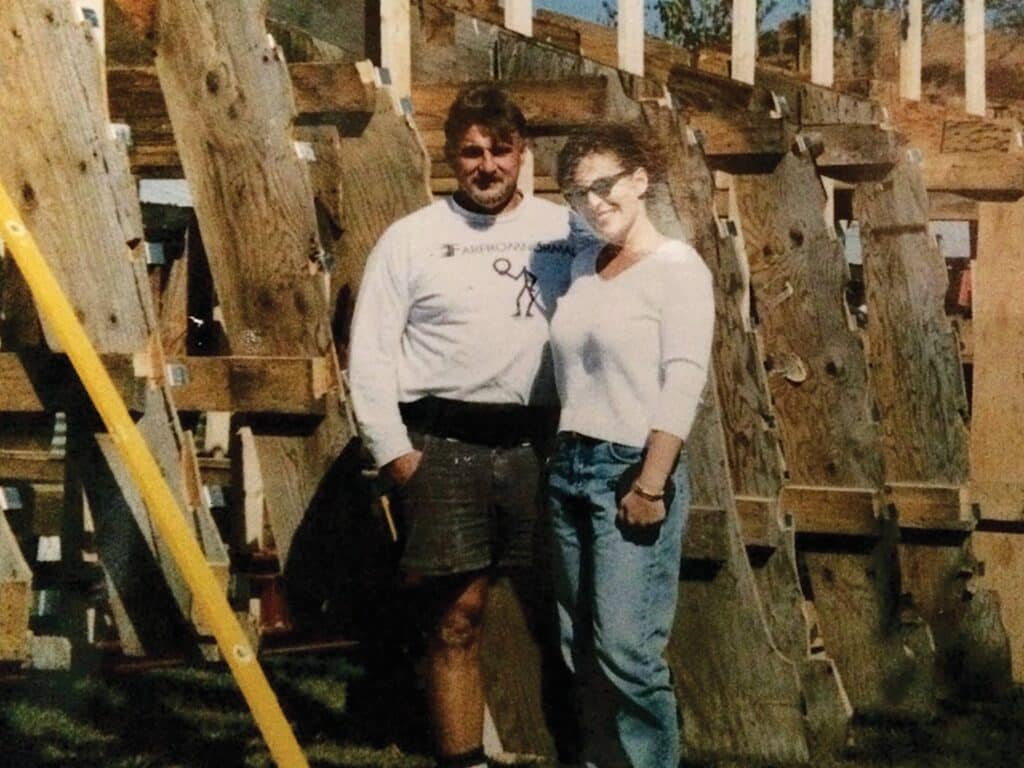

A: When I was doing jobs and fishing in the Carolinas, I would stop by the shops of famous boatbuilders like Buddy Davis, just out of curiosity. I had a production boat at this point with my Bertam, but I wanted something that was more suited for Ocean City. Given my background, I was drawn to it naturally and decided to build my own boat. It wasn’t something I looked at as a business venture when I started. I just wanted to build one for myself. I started my first boat in 1999 using the jigs from an Island Boat Works hull that had been in a fire and were discarded. It was 54 feet that I stretched into a 58-foot model. It was cold-molded with West System epoxy, Okoume plywood and fiberglass. She was built outside of my friend’s chicken coop, and I built a lean-to roof over it to keep it dry. Eventually I closed the walls in around it for the winter so I could heat it. We completed that boat in 2001, and that is when we officially started Titan Yachts. My wife, Linda, thought of the name for the company. We knew we wanted to build the strongest boats on the ocean, so my wife researched it and came up with Titan, from the Greek God known for strength.

After that, I decided I wanted to involve an architect. I got in touch with Darron Roop, who had designed several high-profile boats. Working with Darron, I was able to design the boat how I wanted: big, strong, sturdy and suited for fishing out of Ocean City and the Mid-Atlantic. That boat was a 62-foot build with twin 1,650 hp CATs. I fished that boat up and down the East Coast and put it in the Miami Boat Show, where I made my second sale. And it’s still like that today. The last three boats I’ve started have been for myself, but I’ve ended up selling them!

Q: What makes your boats unique from other custom and production sport-fishers on the market?

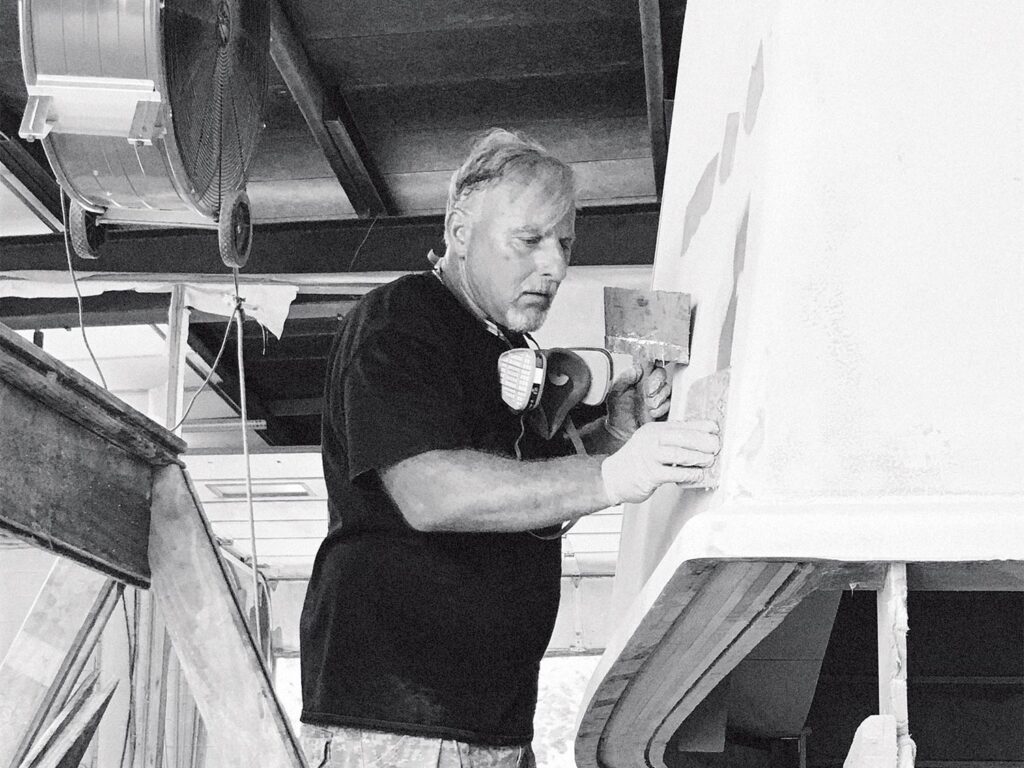

A: From the beginning, we’ve always made our boats purposefully stronger and structurally superior—everything from the foundational components like chines and stringers to the smallest accessories for our hatches. We even epoxy the cabinets into the hull to eliminate shaking, rattling and squeaking. I’ve framed over 10,000 houses and built high-rises in New York City. I know what works and what doesn’t. I know what lasts and what won’t. Of course, with a heavier boat we sacrifice a little on speed. We know that, and our customers know that. We know that on a flat calm day, they beat us. But when it’s 3 to 5, or more, they will be lining up behind us coming in from tournaments.

Q: What has been the key to your success at Titan Yachts?

A: I’ve gone my own way my entire life. I learned a lot from the Carolina builders when I was first getting started, and I’ll listen to people’s advice and opinions. But at the end of the day, I end up going in my own direction. You see that at Titan.

The other things that I’ve tried to do my whole life are put people in a position to succeed and address mistakes right away. When you’re building a house or a boat, people are going to make mistakes. It’s just part of it. The key is to just address it right away and then move on.

Q: What’s next for Titan Yachts and for Russ Garufi?

A: Expansion. We are planning to build a second production facility on the same property as the original. Plans are in preparation to remodel and expand our south building to have the capacity to build four boats simultaneously, and include a new CNC router, and parts and inventory room. We want to increase our production volume so we can work on five boats at a time. Right now we’re at three. We also want to fine-tune our original production facility. We need to if we’re going to keep up with demand, and so I can finally build a boat for myself and not have to sell it! We are also looking at bigger builds. The 70-footer, Lunatico, splashes in a few months, and we are planning on a 68 and a 75. We’re building our boats now with five fuel tanks to hold up to 3,000 gallons for the guys that want to travel on their own bottom.

For me, I’m planning for my next five years and then trying to step back from the day-to-day and fish more. My son, Russ Jr., has been working alongside me for the past two years and is ready to move to the next level. I’m at the shop almost every day, running through boats with my punch list.

We have 35 employees now at Titan, including my son, brother, wife, nephew and others that have been with me from the beginning. We are a family business and want it to stay that way. It’s worked out for us so far. At the end of the day, the main goal is making sure the customer is happy, and that’s what we will keep doing at Titan.