After fishing offshore for 40 years, Peter Cherasia knew he was ready to build a custom boat of his own, but he didn’t know who should build it — until one memorable day in the Bahamas, that is.

“We were in the Pocket at Chub Cay, and it was blowing 28 knots,” Cherasia says. “Bayliss hull No. 10, Man-e-War, passed us up at 30-plus knots, and the captain was drinking a cup of coffee!”

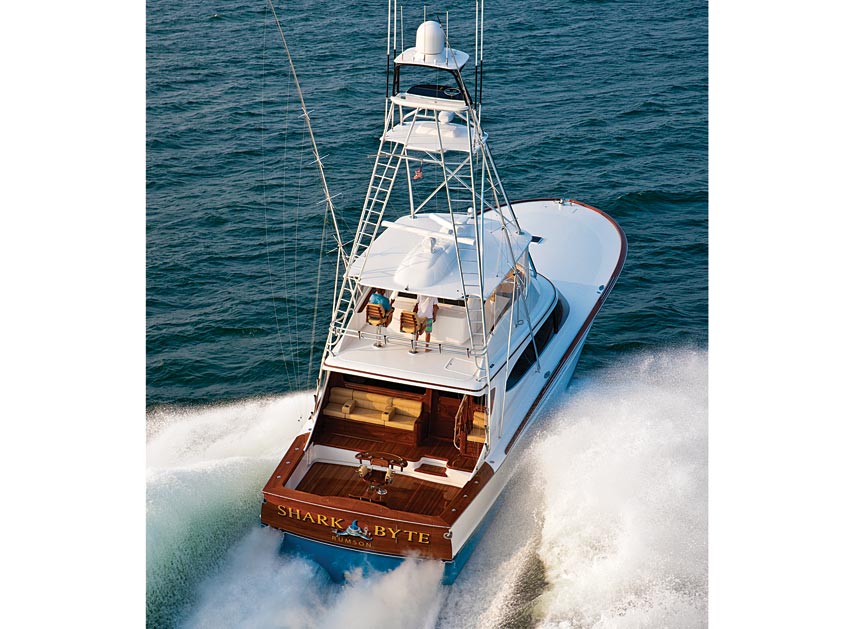

Two years later, Cherasia took delivery of the 73-foot Shark Byte — Bayliss Boatworks’ newest and largest launch to date. The mission of the owner and builder was to take the dry, smooth ride and detailed craftsmanship of a Bayliss-built boat, and add innovative ideas on how to deliver comfort, long-range capability and state-of-the-art technology. The goal being to create, in the words of her captain, Rich Barrett: “the best fishing boat ever.”

Shark Byte primarily fishes for marlin and tuna. She summers in New Jersey, fishes Florida and the Bahamas through March, and then heads to the Caribbean. She’s capable of running on her own bottom (cruise speed during daylight hours and 10 knots at night) to Bermuda. On a recent trip this summer, Barrett and crew released 31 whites in two days. They feel that their mission has been accomplished.

It’s hard not to be mesmerized by her size. Shark Byte was moored bow out, so my initial impression was of her 20-foot-wide, high-gloss, single-piece teak transom, similarly finished aft bulkhead and Release fighting chair. Those pieces stood in beautiful contrast with the bright-white cold-molded hull and flying bridge, with her low-profile sides and the sheen of the subtly designed tuna tower that complements her lines without overwhelming them.

It’s a dead heat, in my opinion, in terms of whether the performance, technology or well-thought-out, minute details steal the show. It’s difficult, though, not to begin with the ride and handling, which I experienced firsthand just after Hurricane Irene wreaked havoc on the area.

The 2,600 hp MTUs came to life, sans smoke. The hydraulic bow thruster, controlled by buttons mounted within the single-lever controls, easily slid the expansive bow between the piles. As Shark Byte idled down New Jersey’s Navesink River and into Ambrose Channel, we managed to dodge several telephone poles. The 73-foot Shark Byte achieved a quick hole shot and a level and quiet ride. We conversed easily, at volumes slightly above library levels, while cruising at 35 knots and turning 1,950 rpm under an 82 percent load. Wide-open throttle was just shy of 45 knots.

When it was time to simulate fighting a fish, Barrett put the screws to the mechanics and spun her 360 degrees, completing the circle in earnest. There wasn’t one clatter, chatter or knock. The underwater gear offered minimal vibration. The GPS read an amazing 8.2 knots when backing down. That’s the fastest I’ve ever gone in reverse. A leftover swell deposited a hot-tub-size volume of water into the teak-soled cockpit, but it evacuated as quickly as it entered, via the excellent drainage setup.

“Our hull design combination has more deadrise, 13½ degrees, aft than a typical Carolina build with a sharper entry. The convex sections forward help us achieve more speed and a softer ride,” Bayliss says.

Under way, the lower chine pushed the water several feet from the hull sides. At trolling speeds, the cockpit remained quiet and the trolling lanes clear.

Flying Bridge

Every square inch of Shark Byte has a purpose, and the design thereof examined and evaluated to the nth degree. The flying bridge is a perfect example.

The center console layout provides room for guests and crew to navigate the entire area. A unique rod storage setup with air-actuated pocket doors holds eight 30- and eight 50-pound outfits on quick-connect mounts. The life raft, a washdown station, and a refrigerated compartment and bait freezer are all stowed forward of the helm. The EPIRB stows out of view in an armrest.

Within the helm, you’ll find a series of wire bundles, neatly secured in and around the electronic modules. Above, and behind clear glass screens supported by polished gas shocks, Bayliss installed four 19-inch monitors to display all the data from the Simrad NSE, Furuno radars and sonars, satellite receivers and cameras.

A control station outfitted with twin VHFs, a Simrad NSE and engine controls sits way on top of the Palm Beach-constructed tower. It’s a comfortable perch, where the multiple occupants can easily wedge in on a rough day.

Cockpit

The business area of Shark Byte looks more like a boardroom than a boat. Wherever your eyes fall, they will not find a single seam in the joinery. The side compartments, such as the ones for the shore power hookups, and doors operate pneumatically. Actuating buttons (where feasible) are hidden from view and away from dripping water.

Every seat, nook and cranny that would accept a door, drawer or hinge has the capability to stow something — an electric grill even pulls out of the bulkhead on the starboard side. (The three-tiered bait compartment has a huge capacity for dredge baits.) Bayliss positions the air-conditioning vents on the bulkhead below the salon window, dumping the cool air directly on the shoulders of the crew seated on the mezzanine.

An extensive ice-making and refrigeration system cools, slushes and freezes where needed. More than 200 feet of copper tubing was used. With the unique transom door, both gate and door function as a single entity; you can land fish easily, without scuffing the brightwork.

Machinery and Construction

Bayliss doesn’t take any shortcuts. “As a builder, we tend to overbuild. To me it’s a good thing; it prevents structural problems now, and 10 or 15 years down the road, the boat will accept higher-horsepower engines with no problem.” the builder says.

The hull sides are 2 inches thick, with two layers of Okoume plywood, an inch of core cell and 6 mm of Okoume, and then bi-axial fiberglass is hand-laid on both sides. The bottom has three layers of Okoume with five layers of glass on the keel and two on the bottom.

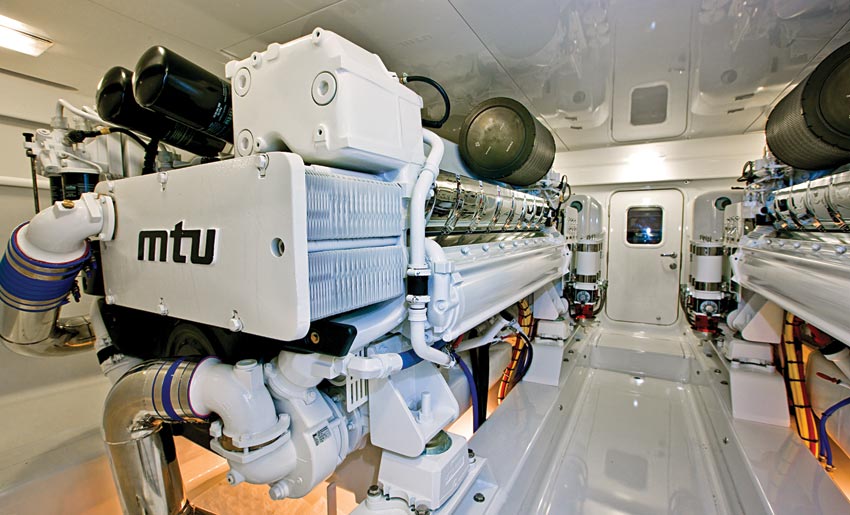

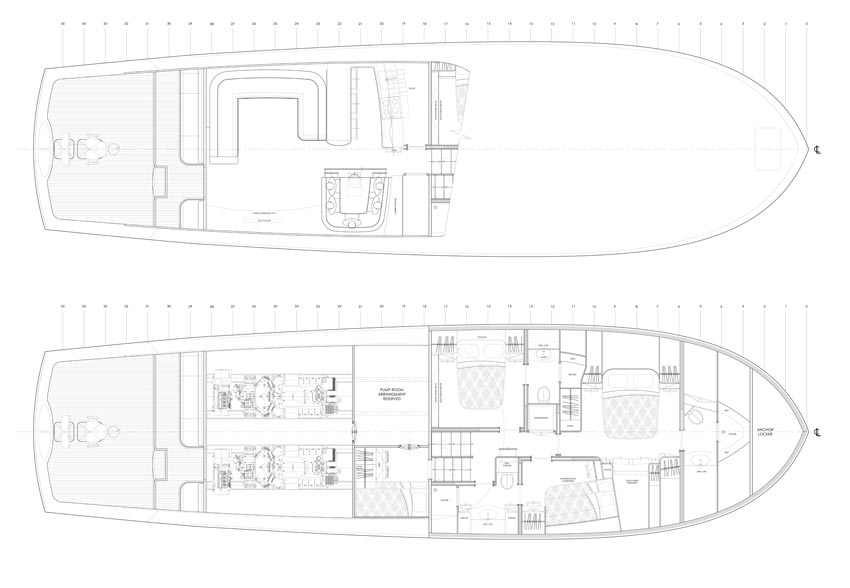

Even the areas hidden from view, such as the centerline tunnel that houses the bilge pump drainage system and bow thruster, are finished in a yachtlike manner. The stand-up engine room is simple and precise. It houses the MTU engines, the DeAngelo exhaust and a set of 30 kW Northern Lights generators contained in custom-design sound shields.

The battery bank sits outboard of the starboard engine, where it is easily accessed. The side-scan sonar mounts amidships, aft in the compartment. The addition of an Eskimo ice maker and a hydraulic tank finish off the space.

The 3½-inch shafts, hooked to a set of ZF gears, use a spline, not a key way system, and are matched to a set of five-blade Veem propellers that get her up to speed.

An air-conditioned pump room houses MTU control units, two 5-ton AC chiller systems, an FCI 1,800-gallons-per-day watermaker, a fuel polisher, a compressor and tank, and two huge raw water pumps. Every pump and system comes with a built-in backup that the captain can easily switch to. Precise engineering was needed, so all are easily accessible for service and replacement.

Interior, Detail and Finish

The detail and craftsmanship of the interior of this four-stateroom, three-head boat exceeds expectations. The salon table sports Bayliss’ custom-made fluted corners, made on a jig and then sent to Release Marine for final completion. All the teak cabinetry and curved trim are fabricated in a similar fashion.

All monitors on the boat are capable of projecting any of the electronics displays or video. They all rise on command or revert to a secure hidden cabinet. Air-actuated pocket doors are used throughout, and each berth offers storage underneath accessed by the same system.

Both the VIP cabin and the captain’s quarters feature truly unique air-actuated, retractable Pullman-style bunks. All cabins are painstakingly accented with teak trim, bountiful lockers, hidden compartments for additional storage, and neat tracts for cell phone and gadget recharging.

The galley and salon continue in the same thread of functionality. There’s abundant seating throughout, and the dinette has its own screen, so the owner and captain can multitask as needed. The galley is spacious, with truly ingenious ways to store cutlery, dishes and utensils. You’ll find functioning drawers where other builders would place a faux front; one splits the drain under the sink — remarkable.

The last piece of wizardry found on Shark Byte involves the lighting and the walk-in AV closet housing the Savant — the control system for the high-tech Vantage lighting system and the onboard video — and the ship’s main electrical panel. With the Savant system, an iPad or iPhone can remotely control almost everything “switchable” in the ship’s systems.

“When you can look back and say there’s not a single thing that we would change, I feel Shark Byte is perfectly designed for the way we fish,” Barrett says. To me, that says it all.

Specifications

LENGTH: 73′

BEAM: 20′

DRAFT: 5’3″

FUEL: 2,850 gallons

WATER: 450 gallons

POWER: 2,600 hp MTU M-94 diesels

Bayliss Boatworks / Wanchese, North Carolina / www.baylissboatworks.com