Special delivery: Sign up for the free Marlin email newsletter. Subscribe to Marlin magazine and get a year of highly collectible, keepsake editions – plus access to the digital edition and archives.

Perhaps never before have there been so many innovative products being introduced in a relatively short period of time. The key points have always been listening to the consumers, finding their pain points in addition to their wants and needs, and then quickly bringing the appropriate solutions to market. But rather than just a roundup of hot new products, we wanted to dive a bit deeper to learn more about the people behind some of these incredible innovations.

Airmar

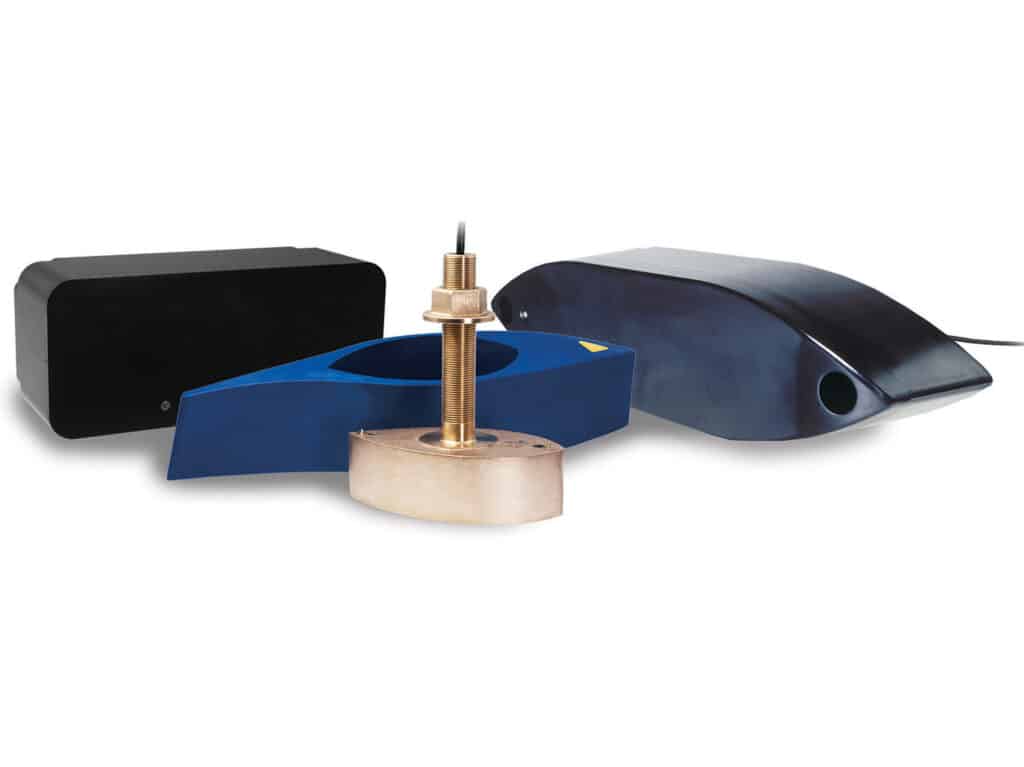

Since fishermen first went to sea in boats of wood, we’ve longed for a clearer, more accurate view of what lies beneath the sea’s surface. Airmar understood this desire and took aim at the goal of greater target discrimination—especially closer to the bottom—when it strove to bring some brand-new sonar technology to the market.

Stephen Boucher, Airmar founder and general manager, says: “It started with the military, first with chirp radar systems, then sonar. Instead of transmitting a pulse at a single frequency, chirp—compressed high-intensity radar pulse—uses an FM transmission where the pulse is initiated at one frequency and ends at either a higher or lower frequency. The greater the frequency spread of the transmit pulse, the greater the target discrimination that can be achieved. The signal-processing technology is relatively well known, but chirp requires broadband transducers that can transmit over a wide frequency band. At Airmar, we understood that creating broadband transducers for medium and high frequencies was possible using composite ceramic technology, but the ceramic material was about 10 times more expensive than the piezo materials used in conventional sport-fishing transducers. Low-frequency broadband transducers simply were not available.”

The first step was to identify the transducer designs needed to make this a reality. “We decided upon three frequency bands,” Boucher says. “We jointly developed a comprehensive line of ceramic elements using a new piezo material covering frequencies from 80 kHz to 500 kHz. Using this new ceramic material, we were able to achieve more than 10 times the bandwidth of conventional transducers, resulting in more than 10 times improvement in discrimination of fish echoes. At low frequencies we achieved the same result using a different design approach. In parallel, we designed a family of transducer housings for different mounting styles and power levels.”

Today, the company’s development program is robust and ongoing. The early work with a core group of engineers and scientists to establish proof of concept took two years, with another three years to fully build out the product line. But the result was an unconventional one: Airmar designed the transducers first, which then enabled the introduction of chirp fish finders. “We worked with all the major manufacturers, promoted the benefits of technology, and supplied sample transducers free of charge as well as technical support,” Boucher says. “What started as our vision became a cooperative effort with our OEM partners to introduce this fundamental advancement in fish-finder technology.”

ElectroSea

When Dr. Louis Cosentino and his son, Daniel, founded ElectroSea in 2016, it was a move born of necessity more than the desire to radically change the landscape of vessel maintenance. “At the core, we’re boaters and fishermen ourselves,” Daniel Cosentino says. “We owned a sport-fisher, and one of the biggest issues we noticed was related to scaling and growth in the cooling systems.” With an extensive background in the medical-device-technology industry—specifically with chemical sterilization and filtration technologies—they were uniquely positioned to not just produce a quick fix but forever alter the way we look at this issue. The initial solution was ClearLine, a product that electrochemically generates a small amount of chlorine from seawater in order to drastically reduce marine growth.

While many innovations take a while to catch on, ClearLine quickly proved its worth. Rather than having to descale systems with harsh and potentially system-damaging chemicals—a time-consuming and messy chore at best—the system prevented growth from occurring in the first place. The next evolution was ElectroStrainer, a system that replaces a vessel’s existing sea strainers with a similar technology that introduces chlorine, at about the same level as tap water, to virtually eliminate growth and fouling.

“We found from our past experiences in medical-device technology that you first need to identify meaningful problems, then examine ways to solve those problems,” Cosentino says. “We are able to do that in several ways. The first is by having a very close relationship with our customers. We have a companywide call every Monday, where everyone can bring up feedback that they’re hearing from our clients. We work backward from the customer’s issues to make value-oriented decisions on what features will be needed and how it will benefit the end user, as well as what not to include.”

He says there are several important keys to this process. The first is having a short time frame from customer input to research and development to product introduction; they call this the fast flywheel method of quickly bringing new products to market. The second key is vertical integration: ElectroSea’s products are designed, engineered, manufactured and marketed internally, then sold via a dealer network and to boatbuilders, both with outstanding technical support. With a laser focus on producing products of the highest quality, again a nod to the medical-device background, each product is designed for very high uptime. Another example: the company’s line of SeaStrong Silver Bullet seal-less magnetic-drive pumps for marine air-conditioning, chiller and livewell systems. Unlike traditional direct-drive pumps that leak at the shaft seals, the SeaStrong Silver Bullet pump has no shaft seal and instead uses a magnetic close-coupled design. It also has an extended run-dry composite pump head and impeller and a stainless housing that resists corrosion.

So what does the future hold? “We’re always looking at those unaddressed areas,” Cosentino says. “When our customers ask us, ‘Can you do this, or solve that problem?’ we see that as an opportunity and a way to create a more enjoyable boating experience. That’s the end goal.”

Gemlux

From his early days of fishing out of a 17-foot Mako around the beaches of Jacksonville and St. Augustine, Florida, Matt Bridgewater was always looking for a better way, starting with a simple rod holder. “Back in those days, our rod holders came with these white inserts,” he says, “and sometimes they’d pull out of the holder along with your rod. They were always covered with this disgusting black mold too. So we always thought, ‘There’s gotta be a better way.’” Although he was headed along a different career path after graduating from college, his father felt Gemlux was underperforming and planned to sell off the company. Bridgewater bought into it instead, where he focused on finding pain points for boatbuilders and owners alike, and designing solutions for those issues. “We started looking at all kinds of products,” he says. “Hinges and latches at first; then it was outrigger bases and just pretty much everything else down the list—always thinking, ‘There has to be a better way to do this.’”

From that philosophy, the Gemlux team turned its attention to outriggers. “We believe the first set of aluminum outriggers was on the Miss Chevy II, which was a wooden Rybovich built in 1947—that’s how long that design has been around,” he says. “And not much has changed since then, either.” On a trip to the Bahamas many years ago, Bridgewater was pulling a pair of squid chain teasers from a set of collapsible aluminum ’riggers in his center-console when a blue marlin attacked one of the teasers. “The pole folded in half and looked like a lobster’s antenna,” he says. “Pretty embarrassing to come back to a crowded marina like that.” Upon returning home after the trip, he located a company that was manufacturing long carbon-fiber poles for the window-washing industry. Light, stiff and strong, they were the inspiration for the Gemlux Bluewater Series carbon-fiber outriggers.

But the product was more of a slow burn than an explosion. “We were three years into the project, and yet no one wanted to demo them,” Bridgewater says. “We bought a Viking 46 Billfish and installed a set on that boat. We fished a full season, then went back and redesigned them for production. So now we’re five years into it, but we do have them ready—we launched at the Viking VIP show; they have them installed on almost all the Valhalla boats and quite a few of their new sport-fish builds.”

So why carbon fiber? First, they won’t corrode and don’t need the constant maintenance and upkeep since they don’t require spreaders and cables for support. And they don’t have issues with crevice corrosion caused by dissimilar metals. They’re flexible but resistant to breakage, not to mention stiff and very strong. “It seems like the dredges are getting bigger and heavier, with double- and now triple-tiered mullet dredges,” Bridgewater says. “That’s really been a game-changer.” The company upgraded its Gemlux demo to a 58-foot Viking and was in the midst of that red-hot billfish bite in the Abacos when we spoke to Bridgewater for this article in early April via Starlink. The team was crushing the white marlin that day, proof that those larger dredges do indeed work. “It’s the innovation that drives us as a company,” he says. “We’re able to remove those pain points where people can enjoy their boats more, enjoy fishing more, and that’s really the name of the game.”

KryptoQuiet

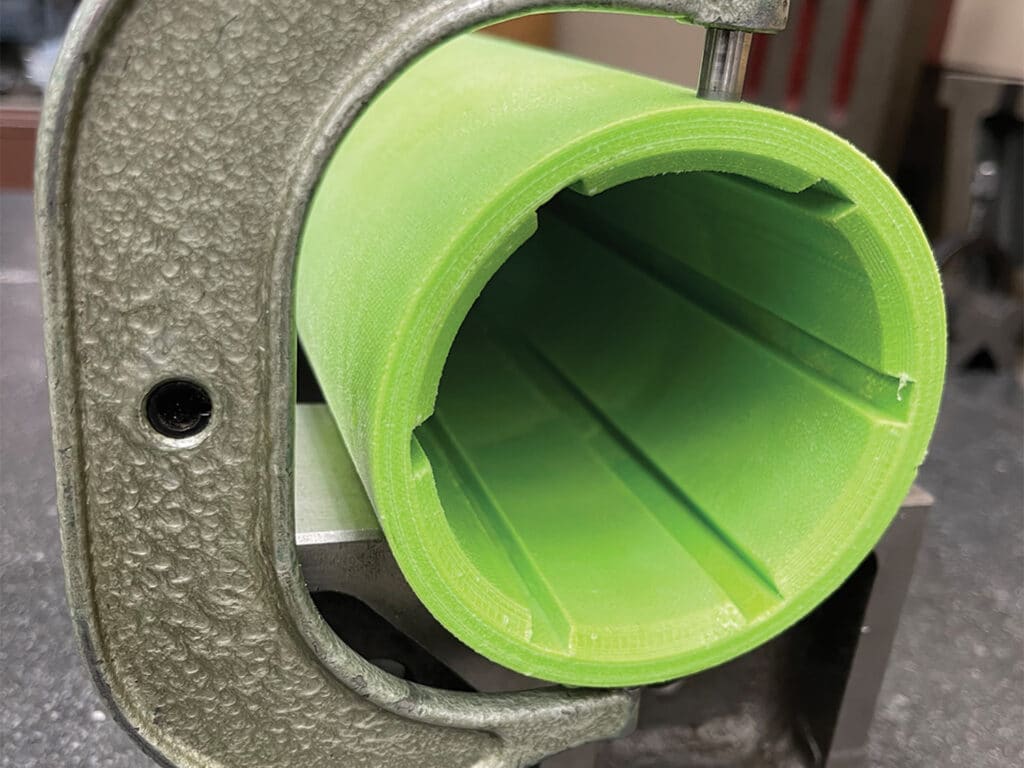

Sometimes tragedy has a way of influencing our lives in ways we don’t even understand until much later. When Steve Drummond’s father was tragically killed in a car accident when Steve was just 14 years old, he felt adrift‚ a rudderless ship at sea. But those early years boating and fishing with his dad instilled in him a sense of wonder of the ocean as well as a familial bond that could never be broken. So after bumming around on motoryachts from Maine to the Caribbean for a while, he ended up back in North Carolina working for a boat dealership. A chance introduction led to a meeting with a business that was producing running gear for a variety of manufacturers, including Hatteras Yachts. Drummond’s family had always owned a Hatteras, even to this day, and he understood the finer points of maintenance. “Cutlass bearings were one of the first things which needed improvement,” he says. “Imagine taking a piece of rubber and grabbing a rotating stainless-steel shaft with it—that squealing sound is what happens with conventional cutlass bearings, and when you slow the shaft down, you lose the ability to create a hydrodynamic wedge to lubricate the bearing.” That led him down the road of testing and developing some new technology that would revolutionize an area that not many had thought of previously.

While much of the product’s composition remains top secret, the final design incorporates thermoplastic

fluoropolymer nanoparticles, which actually bond with the shaft to greatly reduce the friction and noise compared with conventional cutlass bearings. “Then we needed a name,” Drummond says. “I thought about my first set of Kryptonics skateboard wheels, and how slick and smooth they were. And the new bearings were designed to be ultra-quiet, so KryptoQuiet was born.” Today, Drummond has set the running-gear industry on its ear with this product, which doesn’t absorb water and yet remains not just virtually silent but extremely durable, even in use on hard-working charter boats that really rack up the hours each season.

Seakeeper Ride

If you’ve followed the development and adoption arc of the Seakeeper brand of gyrostabilizers, you know it wasn’t an instant success. Gyro technology had been around for hundreds of years, but this was really the first attempt at bringing it to pleasure craft, including sport-fishermen, and as with many new innovations, success was slow in coming. But the company stuck to its guns with the intent of truly transforming the boating experience, and today the Seakeeper name has become synonymous with gyrostabilizers.

The next step was to build further on that concept of a transformational shift in boating, specifically in the way boats handle conditions while underway. So, they started with a blank sheet while also pulling design and engineering assets away from the parent company to form what eventually became known as Seakeeper Ride. “What we did not want to do was design a better trim tab,” says Seakeeper President and CEO Andrew Semprevivo. A career veteran in the marine industry, he started with a summer job at his local marina, then was a sales and project manager for Viking before joining Seakeeper in 2008, just as the company was bringing its gyro technology to market. He was named president and CEO in 2018, and under his leadership the company remains firmly on the line of transformational products.

“At the heart of it really is pitch-and-roll stabilization while underway,” he says. “We wanted a product that would perform at the highest level and would really change the boating experience.” So, with a separate team of engineers, including James Kelly, director of product engineering for Seakeeper Ride, they set out to first tackle the concept of pitch and roll. “We took a physics-based approach,” Kelly says, “which started with the very extensive database we’d developed with Seakeeper on how different hull forms behave in various conditions. Then, we determined how fast we would need to deploy the blades—which meant taking 1,000 calculations to make 100 outputs every second—and then how to do it automatically, without any commissioning, customization or input from the user.” Borrowing technology from the aerospace industry, the company produced a rotary actuator with a sensor package that would automatically control the boat’s attitude in three axes of motion—pitch, roll and yaw—as it moved through the water. It became known as Seakeeper Ride, the first and only vessel attitude control system.

Read Next: Top New Marine Industry Technology for 2024

“We were determined to fulfill our vision of transforming the boating experience for everyone, so we started with the smaller boats,” Semprevivo says. “It was much more difficult this way, but it gives entry-level boaters a better experience and attracts and retains new boaters in the industry, which is important to us all. We’ve accomplished what we set out to do, especially in providing the wow factor.” Semprevivo attributes the brand’s success to the passion and dedication of its employees and looks forward to continuing Seakeeper’s proven legacy of transforming the boating experience.

At its most basic, innovation is simply a multistage process whereby organizations transform ideas into products, services or processes in order to successfully advance, compete and differentiate themselves. Each of these products meets that criteria, but as much as it’s the advancements in technology, it’s also thanks to those incredibly talented people who stand behind them.