Special delivery: Sign up for the free Marlin email newsletter. Subscribe to Marlin magazine and get a year of highly collectible, keepsake editions – plus access to the digital edition and archives.

Fishing has always been a major part of my life. Growing up, I had spent my summers on the Delaware coast with my grandparents on Fenwick Island; as I grew older, boats entered the picture. As long as we were near the water, we owned a boat. Over the years, the fleet included Starcraft and Mako center-consoles; then we eventually graduated to a few Grady-Whites and, in 2018, a new Boston Whaler 315 Conquest. These were ideal vessels for the Delaware Bay and fishing the wrecks up to around 20 miles offshore.

But soon after I retired and found myself with more time on my hands, I realized South Florida was an ideal location for year-round fishing, with a terrific variety including billfish less than 10 miles offshore. After a few visits to Marathon, Key West, Naples and other areas around the Sunshine State, we purchased a residence in Key Largo’s Ocean Reef Club and moved the Boston Whaler there to target sailfish. I had not done a ton of sailfishing in my life, so needless to say, I was in for a big surprise.

After one season, it became apparent that the Whaler did not have the ideal layout for our fishing style. As I started looking around at the kinds of boats in the area, there were two general types: big inboard-powered sport-fishers and long, lean center-consoles with multiple outboards. It was then that I started a process that eventually led to building and owning a beautiful custom boat, but the path was not always easily defined, with plenty of twists and turns along the way.

Examine the Uses

When I set out to purchase a new boat, we had to clearly define our wants and our needs, the must-haves and the nice-to-haves. The most practical person in the decision-making process was my wife, Faye, who would often ask what was wrong with the brand-new boat we had bought just two years before. That certainly helped me get more granular in defining our wants and needs. I started taking serious notes, and I feel this is an area where others in a similar situation might find some benefit.

The first is how we would use the boat, sometimes broken down by percentages of fishing, cruising and overnighting, as this would help define accommodations and other aspects. For me, the primary use would be South Florida sailfishing, with an occasional trip to the Bahamas. Next, would we have a crew or operate on our own? While I planned to be an owner/operator, we set this one aside, knowing it might have an impact on the dimensions down the road.

Next up, restrictions. Even though we had a slip at Ocean Reef, the bylaws set limits on the length and beam, so those were our initial parameters to work with. There were also limits with the boat’s draft relative to not only the marina channel but also any areas we wanted to travel to in the future. This led to discussions about power options—whether to go with diesel inboards or gas outboards.

In the category of “other considerations,” the first was the sun. Medically, it’s not been my friend over the years, so I felt a center-console would not provide enough sun protection. Additionally, on those occasions when family members—more glampers than campers—do want to fish, having an air-conditioned enclosed area that would be out of the weather and a full head that was actually usable were important considerations.

Do the Research

Despite more than 40 years of boat ownership, I soon realized that I didn’t know what I didn’t know regarding builders, layouts and more, so I set about to learn. Now that we had a firmer grasp on how we would use the boat and the amenities we needed, I wanted to gather data, starting with our home port at Ocean Reef. I’d walk the dock on bad-weather days that kept most of the fleet tied up at home; often the captains and crews would be around working on boat projects, so it was a good opportunity to speak with them. This is where being humble and relevant comes in: I already knew that based on my assessments and budget, I didn’t need to spend 30 minutes bending the ear of a captain or mate on a 90-foot Viking, but I also knew these guys understand the industry as well as anyone and have useful insights to share. Most of the Ocean Reef boats were certainly more than we would ever need, so I expanded my search to all kinds of boats in the area. I seemed to learn something new with every discussion I had along the way.

I also studied every brokerage website I could find for manufacturers of boats that might fit our needs, as well as spent time reading industry publications, including Marlin. Faye and I attended the Fort Lauderdale International Boat Show, where we primarily concentrated on production boats. After two days, we still had not found that ideal layout or had that “wow” moment, but we were able to meet several custom-boat builders at the show. Maybe that would be a better option, I thought.

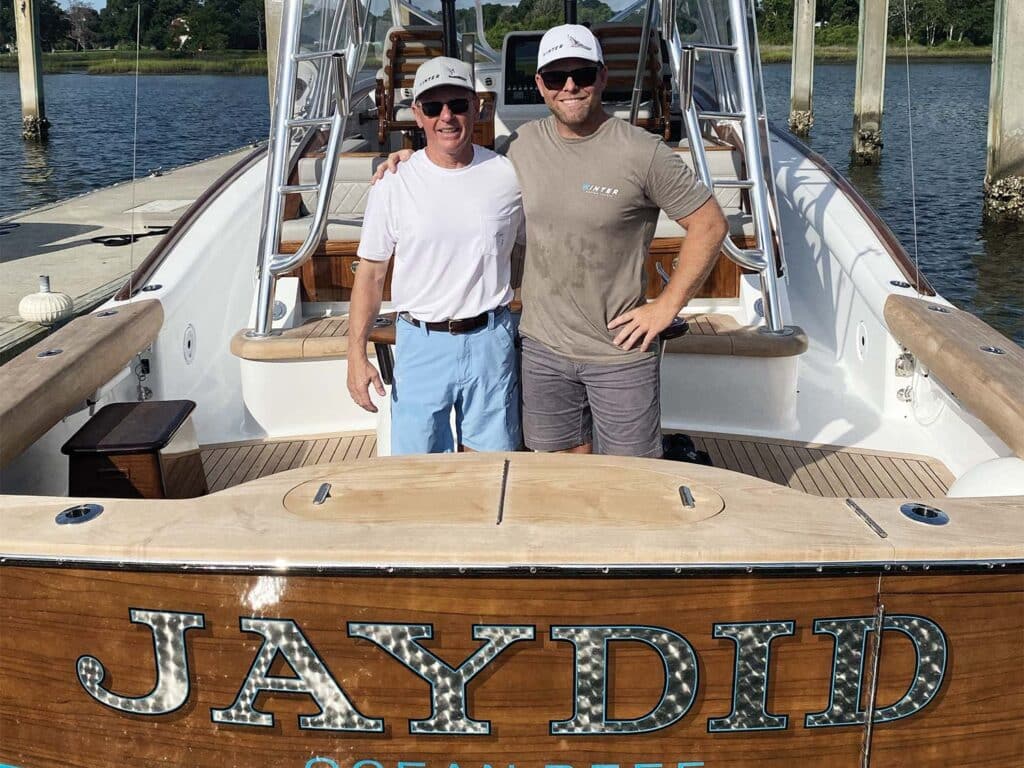

After the show, I went deep on custom builders, and after a few days, I found what I thought would be a perfect fit—a beautiful 46-footer from a well-known boatbuilder in North Carolina. The boat’s walk-around layout was perfect; it had an air-conditioned helm deck and accommodations below for the occasional overnight trips. Unfortunately, my balloon burst just as quickly the following day. I called the builder and inquired about building a 40-footer of the same design that would fit in our bylaw restrictions, but they were backlogged with much larger builds and couldn’t help me. My son Ben dug a bit deeper and located Winter Custom Yachts—they had recently built two beautiful 38-foot walkarounds that were just our size, so I reached out to Tim Winters, and after a few lengthy phone conversations, we made the trip to visit his facility in southeastern North Carolina.

At this point we knew a production boat was not going to meet our needs, and going custom was the answer to get exactly what we wanted. But I also learned that it would take much more than simply visiting a dealer to pick a model, choosing from a short list of options and returning with a check when the finished boat was ready. Winters starts with a blank sheet of paper, just as you would with a custom home.

The Process Begins

Fortunately, Winters had previously built two models that were very similar to what we wanted. However, they had been completed several years earlier; technology had advanced since then, plus Winters had continued to learn with each subsequent build as well. We spent two days at his facility, where he had four boats under construction in each major phase, from jig planking to a recently flipped hull to build-out phase to a nearly completed boat. It was the first time I had witnessed the complexity of building a cold-molded hull. It also gave us a chance to develop the kind of communication and understanding of the build process—along with the challenges that were ahead and ways to address them—that would prove beneficial along the way. After all, we couldn’t just pop over for the weekend to see how things were coming, so developing that trust in the builder is a crucial step in the process. Having a very detailed project plan was also immensely helpful, as this included start and completion dates for key phases of the build.

Although we completed a full design before we started the jig, Winters continually came up with innovative ideas throughout the process. From adding fuel capacity and switching from Cummins to Cat C7.1 engines to give us more space in the engine room to using new composite materials in certain locations to cut down on weight, we were able to adapt throughout the build. The process was very fluid as the design work continued.

To ensure we weren’t missing anything, I had also contacted the owners of the two prior 38-footers Winters had built and asked them, “What would you do differently?” That led to another list of potential design changes—nothing major, but great lessons learned, and fortunately this input was well in advance on the build schedule so those tweaks could be incorporated.

Remain Engaged

Once you begin work on the interior, helm, tower and overall layouts, the trips to visit the builder will increase. On one of these, we brought our Plano tackle storage boxes—in the different sizes and numbers we needed—and developed the ultimate tackle storage center. We spent another two hours with Winters to ensure that I had visibility over the bow while standing or seated at the helm, and when I didn’t, we adjusted the design.

As we neared the end of the build process, we engaged a marine surveyor. When I first mentioned this to Winters, I wasn’t quite sure how he’d react, but fortunately he embraced the idea. The survey was important for me for two reasons: We had a 700-plus-mile trip home to Ocean Reef and I wanted to ensure everything was working before we started our journey, and it also gave me another set of eyes on the build. We provided the completed survey report to Winters, reviewed each item identified, and followed up as the project neared the finish line. It was at this point I asked Winters for a favor: As this was my first custom boat, would he join me and an Ocean Reef captain named Brandon Ram for the trip home? Without hesitation, he said yes.

Ram and I arrived at Winter Custom Yachts five days before our scheduled departure. This gave us both time to recheck those items identified in the survey report as well as touch knobs, operate pumps and ask questions. After four long days, we were ready. By having the builder on the boat for the three-day journey, I could ask questions in real time, and Winters was not bashful about providing tips, suggestions and encouragement when needed. I learned more in those three days than in 40 years of operating a boat previously.

There were a few key lessons I learned along the way. First, be sure you define what you want before you shop for builders. Each one has a different specialty. If they’ve built something in the past that you like, see if the owner will talk to you about it. They can be a great resource. And this is a multiyear relationship between owner and builder—be sure your personalities mesh. Accept the fact that there will be changes to the original design, and that the build process will probably take longer and might cost more than you planned. There will be setbacks, so have plenty of aspirin and antacids on hand for when they arise. Be engaged, visit as often as you can, and double your engagement efforts as the build gets past the 60 percent completion mark. Monitor changes in technology and electronics, and incorporate anything that’s feasible and within the budget. Engage directly with key manufacturers, such as those of engines, towers and controls (big boat shows like the ones held in Fort Lauderdale, Miami and Palm Beach are great places to do this).

Read Next: Our Interview with Tim Winters of Winter Custom Yachts.

In the end, people ask, “Was it all worth it?” Absolutely. We ended up with a beautiful 38-foot custom walkaround that perfectly fits our needs and our wants. The process kept me occupied during my retirement for more than three years, which also made my wife very happy. And about the name? My wife and two kids each put a name in a hat. The first I pulled was Ben’s Boat, which wasn’t going to happen. The second was Jaydid—a bit of a play on words but an indication of my personality as well. Build a brand-new custom boat from scratch? Yep, Jay did.